Pipeline & Industrial Welding Contractor

Nation Wide Welding Services

Family-owned. Field-tested. We deliver safety-first, code-compliant welding solutions that keep your pipeline projects running effectively.

Industrial Welding Services

Welding and Construction Services Include:

Pipeline Construction

Distribution & Station

Regulator Vaults

Coating/Inspection

Renewable/RNG

Mechanical Piping

Nation Wide Welding Service, LLC

Team

Josh Posada

Managing Member

Founded in 2018 by husband-and-wife team Josh and Teresa Posada, Nation Wide Welding Services was born from a deep commitment to quality, safety, and integrity in pipeline and industrial welding.

With decades of combined experience, our mission is simple:

To help contractors and natural gas companies complete critical infrastructure projects efficiently, safely, and to the highest welding standards possible.

Josh, our Owner and Lead Welder, brings hands-on expertise from completing major industrial projects — including full digester installations, active and new pipeline construction, and complex distribution station builds. His deep understanding of field operations ensures every weld is completed with precision and durability.

“You can do anything you wish to do, have anything you wish to have, be anything you wish to be.”— Secrets of the Ages

Key Points to Consider:

25+ Years of O&G Experiance

Industry Experienced Welder

Excellent Safety Record

Carries Welding Qualifications

Fully Insured

Prequalified Rig Welders Available

Twic Qualified

Teresa Posada

Operations Manager

Teresa, our Chief Operating and Marketing Officer, has an Associates Degree in Architectural Drafting & Design and a background with Environmental Systems Design in Chicago, IL. Founded Utica Safety Apparel — a safety supply company that helped shape her commitment to compliance, logistics, and customer satisfaction within the O&G Industry. Today, she oversees operations, client success, and business growth for Nation Wide Welding Services.

We hire experienced welders and labor crews on a project-by-project basis, scaling our team to meet the demands of each job — while maintaining the family-owned service and attention to detail our clients rely on.

“Success is our Duty, Obligation, & Responsibility." — Grant Cardon 10X

Experience Highlights

MEP Engineering - Data Center Division

AutoCAD Coordiantion

Experienced Entrepreneur - O&G Safety Supply Co. 10+ Years

At Nation Wide Welding Service, LLC, our mission is to deliver reliable, high-quality welding and fabrication services that keep our clients’ equipment, infrastructure, and operations running safely and efficiently. We are committed to fast response times, skilled craftsmanship, and dependable service—wherever and whenever our clients need us.

Hear what people have to say about NWWS

Good man and a good company. Give them a shout if you need help. Thanks.

Great company to work for!

At the end of the day I owe Josh Posada a lot. He gave me a once in a life time opportunity. I got the opportunity to work in the northeast and I learned a lot more in my welding trade. The lessons I've learned helped me grow in my trade and for who I am. I've been a Project Manager because of the responsibilities Josh gave me. He taught me a new skill with down hill which helped me later down the road.

Frequently Asked Questions

What steps do you take to ensure the quality and safety of your welding work?

At Nation Wide Welding, quality and safety are at the core of our operation. Our welders are highly trained and experienced in Rig Welding, and we keep all equipment and materials meticulously maintained to ensure they perform as intended. Every job begins with a site safety meeting, and our team participates in ongoing safety training through a professional safety services firm. We follow standardized operating procedures, daily safety reviews, and our excellent record is documented with ISNetworld. For projects governed by utility company standards, all critical welds are professionally x‑rayed and inspected before the project completion. Additionally, our welders meet the specific qualifications required by the utility companies we serve, ensuring that every project adheres to the highest industry standards.

What kind of projects have completed in the past?

Nation Wide Welding Services has a proven track record across a wide range of natural‑gas and industrial projects. Our portfolio includes large‑scale distribution pipeline installations—such as 12‑ and 20‑inch steel mains extending over several miles, and a 6‑inch steel river crossing. We have also delivered mechanical piping installations for facilities like Dartmouth College, fabricating and installing heating and cooling systems for campus expansions. Our crews prefabricate and install underground regulator vaults and similar distribution infrastructure.

In the renewable-energy space, we fabricated and installed a 130 k MMBtu/year natural‑gas digestor in Maine. We also contributed to the state’s first renewable natural gas dairy digester, where the mechanical scope involved process pipe fabrication in HDPE, stainless steel, carbon steel and PVC, installation of manure‑handling equipment and heat exchangers, and pressure testing and commissioning. Our 2024 work includes a 4‑inch steel Archaea pipeline project with welding, coating, testing and excavation services.

This breadth of experience—spanning steel and stainless pipe welding, HDPE and PVC fabrication, mechanical piping, equipment installation and underground utility work—allows us to confidently take on complex natural‑gas distribution and industrial projects of varying size and material requirements.

How do you price your services?

We offer two pricing models—time‑and‑materials and per‑project—to suit the needs and scope of each job.

Time‑and‑materials: This model bills for the actual hours worked and the materials consumed. Before the project begins, we establish hourly labor rates, equipment costs and any applicable mark‑ups. As work progresses, we provide detailed invoices showing the time spent, who performed the work, and the materials used. This approach offers flexibility when the scope may evolve, since you pay only for the work completed and materials required; changes do not require renegotiation.

Per‑project (fixed) pricing: For projects with a well‑defined scope, we can agree on a single total cost up front. This fixed price encompasses labor, materials and other expenses. Because the price is predetermined, clients have a clear understanding of their financial commitment and contractors are motivated to work efficiently. This option is ideal when the work is straightforward and the variables are understood.

By offering both models, we provide flexibility for projects that may change over time, while also giving clients the option of a predictable, all‑in price when the scope is well defined.

Please contact us directly to request pricing details for your project: (315) 873-8100

What certifications or qualifications do your welders hold?

Our welders are qualified to meet a wide range of industry standards and utility‑specific requirements. They hold certifications under recognized codes such as the American Welding Society’s D1.1 structural steel standard and ASME Section IX for pressure piping, which certify proficiency in welding materials and joint types commonly used in natural‑gas distribution and industrial installations. For pipeline projects, our welders are qualified to the API 1104 standard, which sets strict guidelines for the welding of pipelines and related facilities, ensuring welds withstand the pressures and operational conditions found in gas transmission systems.

Every certification requires testing under a written welding procedure specification (WPS), and our team is regularly requalified to ensure ongoing compliance. Additionally, we maintain Certified Welding Inspector (CWI) oversight and keep qualifications current through continuous training and safety programs. We also obtain any additional qualifications mandated by the utility companies we serve, ensuring that each project meets the specific standards and codes required by our clients.

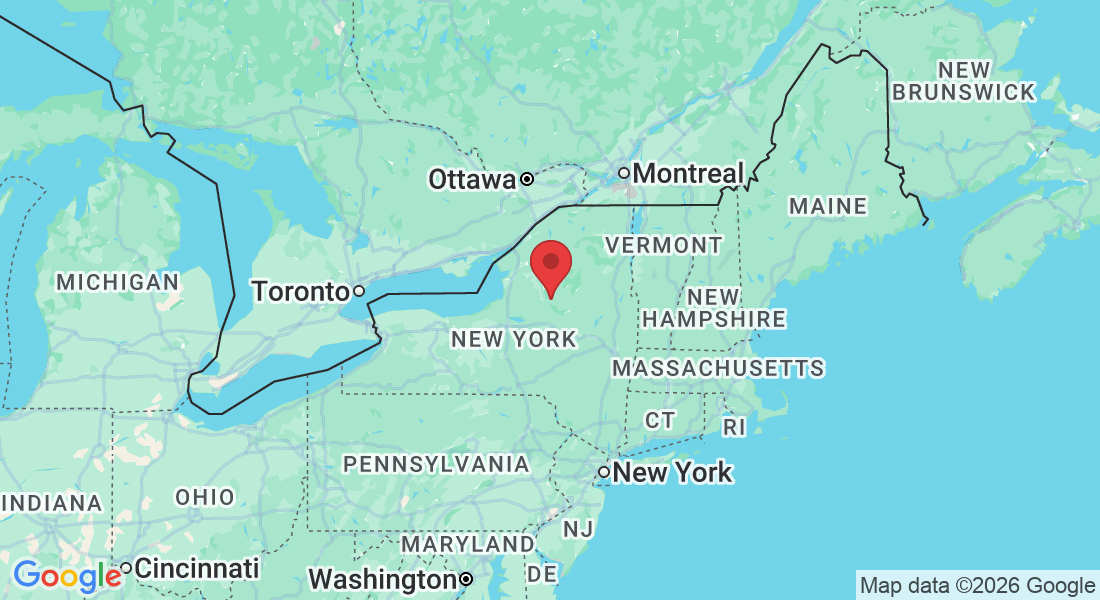

Do you provide on-site welding services, and if so, which areas do you cover?

Yes. Nation Wide Welding Services offers fully mobile, on-site welding for natural‑gas and industrial projects. Our teams operate rig welding trucks fully equipped with all necessary tools, allowing us to perform pipeline, distribution and mechanical welding, on-site.

Over the past six years we have served clients throughout the New England region—including projects in Maine, Massachusetts, Vermont and Rhode Island—and we are expanding our services into New York. Whether you need support for distribution main installations, mechanical piping in a facility or prefabricated regulator vaults, we can mobilize to your location to deliver high‑quality welding and fabrication work in the field.

2026 © Copyright Nation Wide Welding Service, LLC

All rights reserved.